Festo supports Automation Industry with Core Range

This year, the South African government imposed strict restrictions as an attempt to suppress the spread of Covid-19. As a result, the restrictions have had a ripple effect on the economy and industries such as the Automotive, Food and Beverage, Textile and the Medical industry. The Festo Core Product Range, also known as Stars in Automation offers solutions that support Automation Industries during these times.

The Core Product Range offers the latest technologically advanced solutions that assist customers in becoming competitive without compromising on high quality at attractive prices. Festo is helping companies cut down costs and realise up to 80% applications in the industry effortlessly through these selected products. “As a preferred partner in the Automation Industry, we look at our customer’s challeng[es and design high performing solutions to overcome them. This is why we recommend the latest Core Product Range to our customers that require products with optimal price-performance ratio” said Adrian Bromfield, Head of National Sales at Festo South Africa.

The hallmark of the latest Core Product Range is the collaboration between the design engineers and production planners from Festo; they worked closely together during the development of these products to ensure that the products meet customer needs. According to a research institution, Meticulous Research, the overall estimated impact of COVID-19 in the Automation Industry is 7-8%. As leaders in this industry, Festo recognises the vital role of supporting the industry through this pandemic. These products are one of the initiatives that they are using to support their customers. Below are some of the Core Range Product highlights and features that customers can expect from Festo.

Smallest slide drive in the market

The Festo Mini Slide DGST is strong when it comes to precision, forces, motion control, durability and reliability. The yoke and slide are manufactured fully automatically as a single part. In addition, the developers successfully reduced the number of components by 60% compared with the previous model. This enables the DGST to be produced in large quantities with maximum efficiency and cost-saving.

Available in a twin-piston design with diameters of 6-25mm and stroke lengths of 10-200mm, the slide houses the integrated guide and the endplate - all manufactured from a single part, eliminating torsion, misalignment and providing precise movements. Impact shocks at the end of the stroke are reduced by the integrated cushioning elements, seated within the body length. With built-in stroke adjustment, the DGST eliminates the need for additional parts, saves space and ensures top performance for your applications.

Flexible adaption to applications

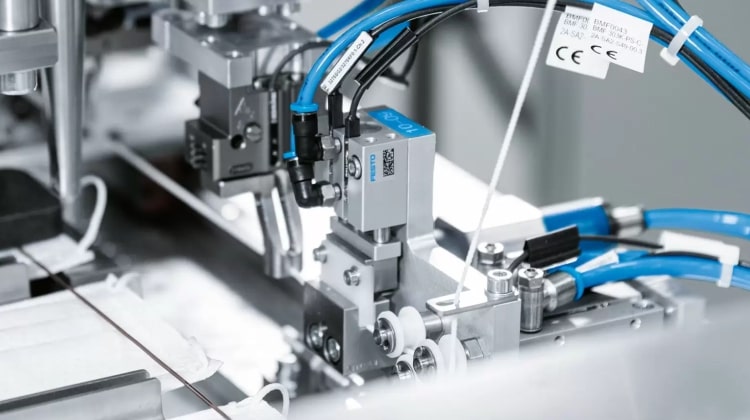

Reliability is standard with the guided cylinder DFM. This impressive guided drive has the best price/performance ratio in the market and offers optimum guide characteristics, sturdiness and flexibility. It is reliable, adaptable and resilient – even with high torques. With its two different guide variants, the DFM can move on average over 100% higher loads than its competitors. It adapts flexibly to every application thanks to a choice of assembly and air port options. The combination of linear drive and powerful guide unit means that the DFM can reliably move high loads, even in tight spaces.

For example, the recent pandemic has resulted in a strong demand for mouth and nose protection masks worldwide. With Festo technology and pneumatic components from the Core Product such as the attractively priced DFM, the mechanical engineering company Mikron has developed a system that allows practically anyone to produce masks themselves. The electrical and pneumatic components from the core range installed in the Mikron plant can be delivered quickly worldwide so that the plant can be constructed decentrally at locations around the world.

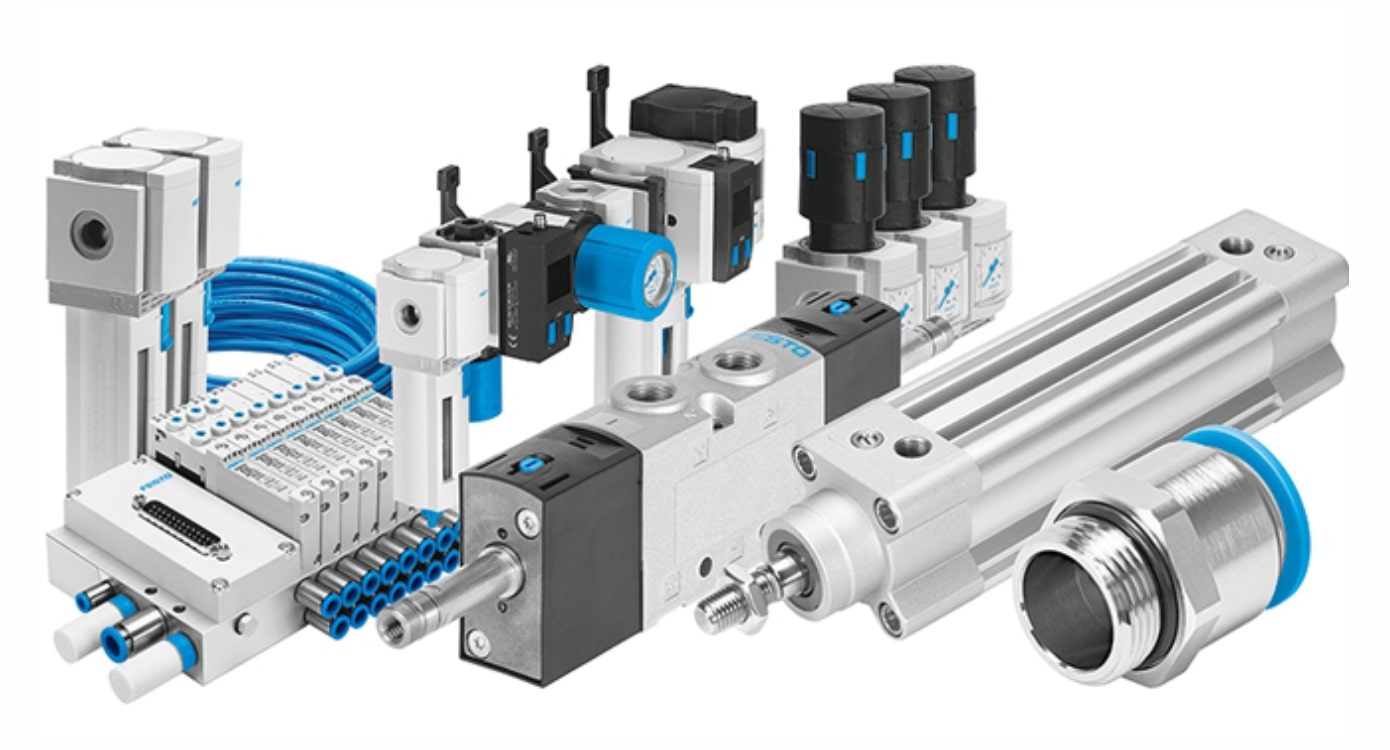

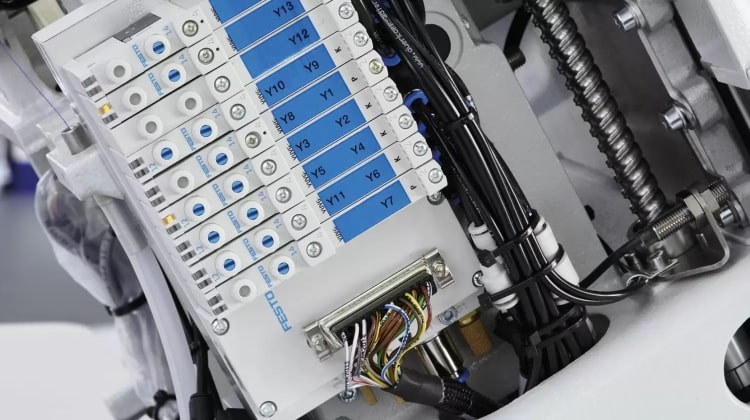

2 200 products to choose from

The core product range includes over 2 200 components from every phase of the pneumatic and electrical control chain – from compressed air preparation, valves and cylinders to accessories, such as matching tubing and fittings. Several components marked with a star on the Festo website are typically in stock locally and ready to be ordered. Products in the Core Product Range are proven Festo quality with high logistics performance thanks to automated production at various decentralised locations. “We pride ourselves by offering products that give customers peace of mind in tough times and allow them to concentrate on their core competencies”, concluded Bromfield.

Source: Festo

Related Posts

Festo makes seamless connectivity a reality

Festo makes seamless connectivity a reality The cloud is everywhere. We save data on the…

Festo supports Automation Industry with Core Range

Festo supports Automation Industry with Core Range This year, the South African government imposed strict…

New Festo valves gain immense popularity

New Festo valves gain immense popularity Valves are one of the critical components for pneumatic…